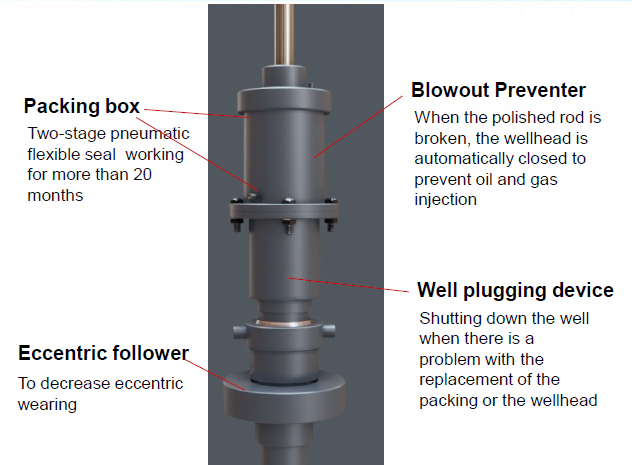

Outstanding advantages of pneumatic flexible polished rod stuffing box:

l It can adapt to the tiny swing of polished rod and reduce eccentric wear

l It can reduce the wear of polished rod and packing,

l It can improve utilization of packing materials

l It can increase packing replacement cycle by times

l It can improve the service life of packing and polished rods

l It can reduce the maintenance of polished rods and stuffing box

Working principle:

l Type C inflatable rubber ring, filled with high-pressure gas, continuously and evenly pressurize the packing;

l The spiral structure of the packing can shrink under the action of gas pressure to ensure that the packing and the polished rod are closely attached at any time, improve the utilization of the packing, and increase the replacement cycle;

l Low friction, reduce the wear of polished rod and packing, and increase the service life of packing and polished rod;

l The rubber ring is filled with fluid gas, which can adapt to the slight swing of the polished rod, reduce partial wear, and increase the service life of the packing and polished rod.

l When the polished rod moves up and down, the packing box realizes a two-level or three-level flexible dynamic seal to the polished rod;

l When the packing box needs maintenance or treatment of the well head, temporarily shut down the plugging device;

l The eccentric follower provides 13mm horizontal displacement compensation and plus or minus 15° vertical swing compensation for the polished rod;

l When the polished rod breaks down, the blowout preventer is automatically closed to prevent blowout and oil leakage.

Technical Parameters

Diameter of polished rod | 22mm – 44mm (7/8” to 1 3/4”) |

Woring Temperature(゚C) | -50 - 250 |

Connections | 3" Thread (customizable) |

Max horizontal deviation distance | 13mm (1/2”) |

Max horizontal deviation angle | Any angle |

Max vertical swing angle | -15゚-15゚ |

Height | 440mm-480mm (1.44’-1.57’) |

Diameter | 189mm( 7.44”) |

Weight (Kg) | 22-25 |

Max wellhead pressure | 3000psi (25Mpa) |

CopyRight @ 2021, All Rights Reserved by Shandong Dream Clean Tech Co., Ltd

Technical Supports:KASON